High Silica Continuous Yarn for 1000℃ temperature resistance sewing or weaving

Performance, Characteristics & Applications

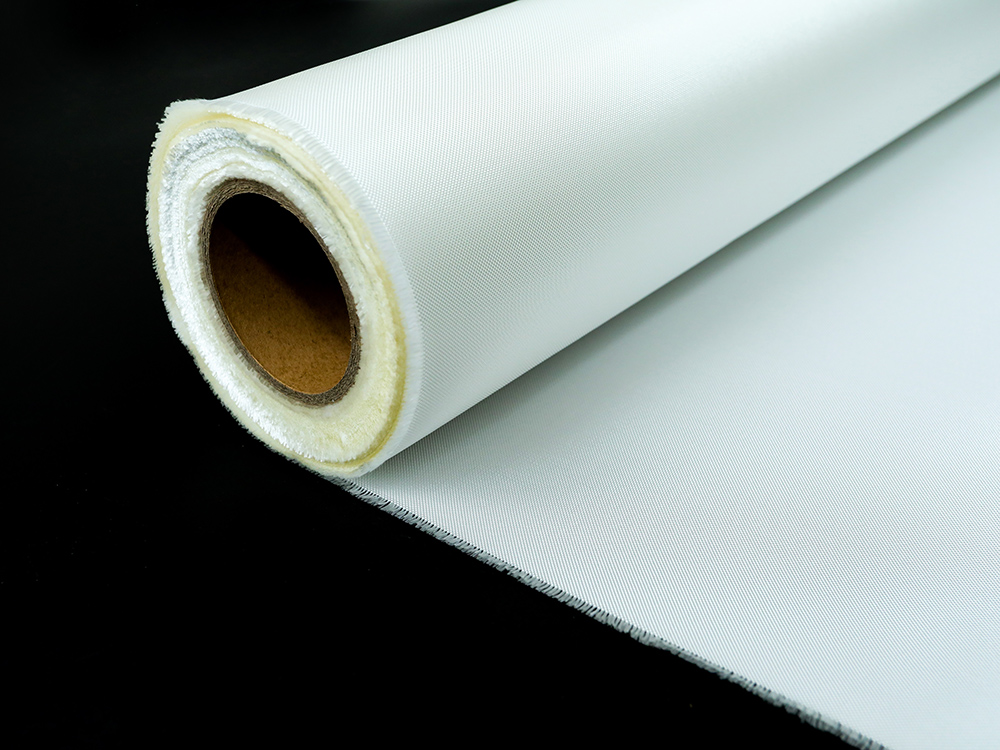

High-silica continuous yarn is a high-silica continuous yarn processed by acid treatment, heat treatment and surface coating of original glass fiber yarn. The operating temperature is 1000 ℃ .

Main applications: weaving, sewing and bundling of high temperature resistant fabrics, winding heating wires and heating elements, ther- mal insulation materials, seals etc, such as sleeves, sewing threads, electronic cigarette cores, etc.

Product Description

High silica continuous yarn has the characteristics of high temperature resistance, ablation resistance, strong processing adaptability and wide use. It can be used for sewing, binding, winding, weaving and other production requirements of high-temperature products. It can be used stably at 1000 ℃ for a long time, and the instantaneous heat resistance temperature can reach 1450 ℃.

It is widely used in sewing high-temperature fabrics, weaving high-temperature sleeves, winding high-temperature components, making high-temperature seals, etc.

High Silica Continuous Yarn can use coatings such as PTFE and coupling agents to adapt to more needs for sewing and weaving, and can be customized according to specific customer needs.

Technical Data Sheet

|

Spec |

Diameter (mm) |

Linear Density (tex) |

Tensile Strength (N) |

SiO₂ (%) |

Water Content (%) |

Oiliness (%) |

Temperature (℃) |

|

HCT9-200SB |

0.45±0.05 |

200±20 |

≥40.0 |

≥96 |

≤3 |

18.0±2.0 |

1000 |

|

HCT7-216SB |

0.45±0.05 |

216±20 |

≥54.0 |

≥96 |

≤3 |

18.0±2.0 |

1000 |

Note: Can be customized according to customer requirements.